Under this head the reader may be reminded that among most American tribes each family produces and manufactures for itself. There is a more or less definite division between the work of men and women, but beyond that there is little specialization. The individuals are not of equal skill, but still each practices practically the whole gamut of industrial arts peculiar to his sex. This fact greatly increases the importance of such arts when considered as cultural traits.

Fire making

The methods of making fire are often of great cultural interest. So far as our data go, the method in this area was by the simple fire drill as shown in the Shoshoni collections, Fig. 17. Some of the Wood land tribes used the bowdrill but so far, this has not been reported for the Plains. It may be well to note that to strike fire with flint one must have some form of iron and while pyrites was used by some Eskimo and other tribes of the far north, it seems to have been unknown in the Plains. Naturally, flint and steel were among the first articles introduced by white traders.

Textiles and Skins

While in a general way, it is true that the Plains Indians used skins instead of cloth and basketry, it cannot be said that they were entirely unfamiliar with the basketry art. Of true cloth, we have no trace. Blankets woven with strips of rabbit fur have been noted and on certain Osage war bundles, we find covers coarsely woven of thick strands of buffalo hair; these are about the only traces of true weaving.

Baskets

On the other hand, baskets were more in evidence. The Shoshoni and Ute were rather skilful, making and using many varieties of baskets. The Nez Perce made a fine soft bag like their western neighbors. The Hidatsa, Mandan, and Arikara made a peculiar carrying basket of checker weave, and are also credited with small crude, coiled baskets used in gambling games. It is believed by some students that the last were occasionally made by the Arapaho, Cheyenne, Kiowa, and Dakota. The Osage have some twined bags, or soft baskets, in which ceremonial bundles are kept, but otherwise were not given to basketry. The Omaha formerly wove scarfs and belts. On the south, the Comanche are believed to have made a few crude baskets. Woven mats were almost unknown, except the simple willow backrests used by the Blackfoot, Mandan, Cheyenne, Gros Ventre, and others. These are, after all, but citations of exceptions most pronounced among the marginal tribes, the fact being that the Plains area as a whole is singularly weak in the textile arts.

Since skins everywhere took the place of cloth, the dressing of pelts was an important industry. It was not only woman s work but her worth and virtue were estimated by her output. Soles of moccasins, parfleche, and other similar bags were made of stiff rawhide, the product of one of the simplest and perhaps the most primitive methods of treating skins. The uppers of moccasins, soft bags, thongs, etc., were of pliable texture, produced by a more elaborate and laborious process.

For the rawhide finish the treatment is as follows: Shortly after the removal of a hide, it is stretched out on the ground near the tipi, hair side down, and held in place by wooden stakes or pins such as are used in staking down the covers of tipis. Clinging to the upturned flesh side of the hide are many fragments of muscular tissue, fat, and strands of connective tissue, variously blackened by coagulated blood. The first treatment is that of cleaning or fleshing. Shortly after the staking out, the surface is gone over with a fleshing tool by which the adhering flesh, etc., is raked and hacked away. This is an unpleasant and laborious process requiring more brute strength than skill. Should the hide become too dry and stiff to work well, the surface is treated with warm water. After fleshing, the hide is left to cure and bleach in the sun for some days, though it may be occasionally saturated by pouring warm water over its surface. The next thing is to work the skin down to an even thickness by scraping with an adze-like tool. The stakes are usually pulled up and the hard stiff hide laid down under a sun-shade or other shelter. Standing on the hide, the woman leans over and with a sidewise movement removes the surface in chips or shavings, the action of the tool resembling that of a hand plane. After the flesh side has received this treatment, the hide is turned and the hair scraped away in the same manner. This completes the rawhide process and the subsequent treatment is determined by the use to be made of it,

The soft-tan finish as given to buffalo and deer hides for robes, soft bags, etc., is the same in its initial stages as the preceding. After fleshing and scraping, the rawhide is laid upon the ground and the surface rubbed over with an oily compound composed of brains and fat often mixed with liver. This is usually rubbed on with the hands. Any kind of fat may be used for this purpose though the preferred substance is as stated above. The writer observed several instances in which mixtures of packing house lard, baking flour, and warm water were rubbed over the rawhide as a substitute. The rawhide is placed in the sun, after the fatty compound has been thoroughly worked into the texture by rubbing with a smooth stone that the heat may aid in its further distribution. When quite dry, the hide is saturated with warm water and for a time kept rolled up in a bundle. In this state, it usually shrinks and requires a great deal of stretching to get it back to its approximate former size. This is accomplished by pulling with the hands and feet, two persons being required to handle a large skin. After this, come the rubbing and drying processes. The surface is vigorously rubbed with a rough-edged stone until it presents a clean-grained appearance. The skin is further dried and whitened by sawing back and forth through a loop of twisted sinew or thong tied to the under side of an inclined tipi pole. This friction develops considerable heat, thereby drying and softening the texture. As this and the preceding rubbing are parts of the same process their chronological relation is not absolute, but the usual order was as given above. The skin is then ready for use.

Skins with the hair on are treated in the same manner as above, except that the adze-tool is not applied to the hair side. A large buffalo robe was no light object and was handled with some difficulty, especially in the stretching, in consequence of which they were some times split down the middle and afterwards sewed together again.

Among some of the Village tribes, it seems to have been customary to stretch the skin on a four-sided frame and place it upright as shown in the exhibit for the Thompson Indians (south side of the Jesup North Pacific Hall) . The exact distribution of this trait is not known but it has been credited to the Eastern Dakota, Hidatsa, and Mandan. The Blackfoot sometimes used it in winter, but laid flat upon the ground.

Buckskin was prepared in the same manner as among the forest tribes. The tribes of the western plains were especially skilful in coloring the finished skin by smoking. There were many slight variations in all the above processes.

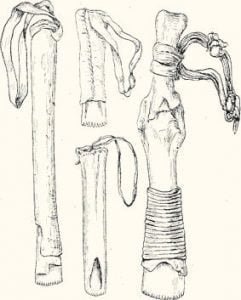

The adze-like scraper was in general use throughout the Plains and occurs elsewhere only among bordering tribes. Hence, it is peculiar to the buffalo hunting tribes. The handle was of antler, though occasionally of wood, and the blade of iron. Information from some Blackfoot and Dakota Indians indicates that in former times the blades were of chipped stone, but the chipped scraper found in archaeological collections from the Plains area cannot be fastened to the handle in the same manner as the iron blades, the latter being placed on the inner, or under side, while the shape of the chipped stone blade seems to indicate that it was placed on the outside. Hence, the former use of stone blades for these scrapers must be considered doubtful. The iron blades are bound to the wedge-shaped haft, which each downward blow, when the tool is in use, forces tightly into the binding. When the pressure is re moved the blade and binding may slip off. To prevent this, some tools are provided with a cord running from the end of the handle once or twice around its middle arid thence to the binding of the blade. Again a curved iron blade is used, one end of which is bound near the middle of the handle. These types (Fig. 21) are widely distributed throughout the Plains, but the curved iron blade seems to be most frequent among the Arapaho and Cheyenne, and wooden handles among the Comanche.

On the other hand, fleshing tools, chisel-shaped with notched edges, were used throughout Canada east of the Rocky Mountains, and in many parts of the United States. Hence, they cannot be taken as peculiar to the Plains. The older type of flesher is apparently the one made entirely of bone, while the later ones were made entirely of iron. Sometimes an intermediate form is found in which a small metal blade is fastened to the end of a bone shaft (Fig. 22). The shaft of the flesher is usually covered with rawhide and to its end is attached a loop for the wrist. The iron flesher seems to be the only type peculiar to the Indians of the Plains. The distribution of the bone flesher is such that its most probable origin may be assigned to the Algonquin tribes of the Great Lakes and northward.

The production of soft buckskin usually necessitates a peculiar process called beaming, in which the skin is laid over the rounded surface of a tree section and scraped with a tool suggesting a draw-shave. Beaming tools are thus identified with the dressing of deerskins and in this respect stand distinct from the adze-tool used in dressing buffalo skins. They seem to be used wherever the dressing of deerskins is prevalent and are best known under the following types:

- split leg bones

- combined tibia and fibula of deer or similar animal

- rib bone; d, wooden stick with metal blade in middle, stick usually curved

From the collections in this Museum it seems that the split leg bone type is not found in the Plains. Should further inquiry show this to be the case, it would be a matter of some interest since the split bone type is found in archaeological collections from British Columbia, Ohio, and New York, and is therefore of great antiquity as well as wide distribution. In any case the data for historic times indicate that some form of beaming tool is a concomitant of deerskin dressing from Alaska and California (the Hupa) to Labrador, and Pennsylvania.

The rubbing with a rough stone is the usual treatment accorded deerskins, and cannot be considered peculiar to the Indians of the Plains.

Tailoring

The garments of the Indians of the Plains were simple in construction, and the cutting of the garment was characterized by an effort to make the natural shape of the tanned skin fit into the desired garment, with as little waste as possible. (Fig. 15.) We do not know how skins were cut before the introduction of metal knives by white traders. Needles were not used by the women among the Plains Indians, but the thread was pushed through holes made with bodkins or awls. In former times these awls were made of bone; the sewing was with sinew thread made by shredding out the long tendons from the leg of the buffalo and deer. When sewing, Blackfoot women had at hand a piece of dried tendon from which they pulled the shreds with their teeth, softened them in their mouths and then twisted them into a thread by rolling between the palms of their hands. The moistening of the sinew in the mouth not only enabled the women to twist the thread tightly, but also caused the sinew to expand so that when it dried in the stitch it shrank and drew the stitches tight. The woman’s ordinary sewing outfit was carried in a soft bag of buffalo skin and consisted of bodkins, a piece of sinew, and a knife. Bodkins were sometimes carried in small beaded cases as shown in the exhibit.

5